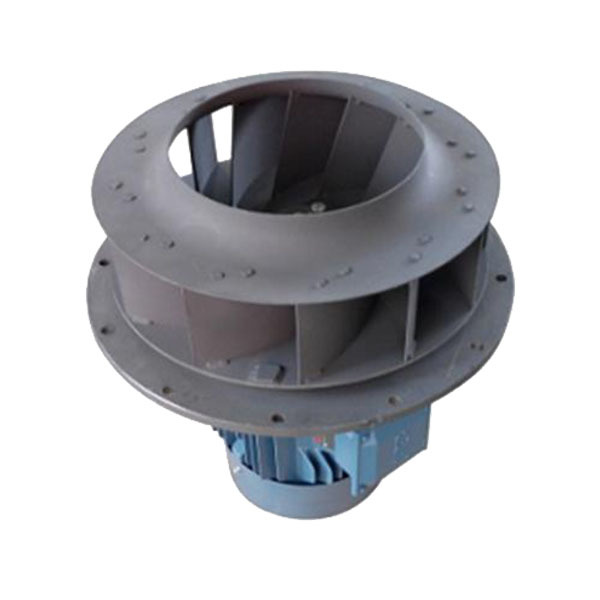

Shutdown procedure for Centrifugal fan from China manufacturer

2022-04-28

1. Emergency shutdown: During the trial operation of the unit, if one of the following situations occurs, emergency shutdown should be performed immediately. The operation of emergency shutdown is to press the stop button of the main motor, and then carry out the aftercare work after the shutdown.

1.Centrifugal fan from China manufacturer suddenly has strong vibration and has exceeded the trip value.

2. There is scratching or abnormal friction sound inside the body.

3. There is smoke at any bearing or seal, or the temperature of a bearing rises sharply to the alarm value.

4. When the oil pressure is lower than the alarm value and cannot return to normal.

5. The liquid level of the fuel tank is low, and there is a phenomenon of suction.

6. The shaft displacement value shows an obvious continuous increase, when it reaches the alarm value.

2. Normal shutdown: The normal shutdown of the unit shall be operated according to the following procedures.

1. Gradually open the vent valve (or outlet bypass valve), while gradually closing the exhaust valve.

2.Centrifugal fan from China manufacturer gradually close the intake throttle to 20-25°.

3. Press the stop button and pay attention to whether there is any abnormal phenomenon during the shutdown.

4. The oil supply can be stopped after the unit stops for 5 to 10 minutes, or when the bearing temperature drops below 45°C. For units with floating ring seals, the seal oil pump must continue to supply oil until the body temperature is lower than 80°C.

5. After the unit is stopped, the rotor should be rotated 180° regularly within 2 to 4 hours.