quality Centrifugal fan price Noise reduction treatment method

2022-05-12

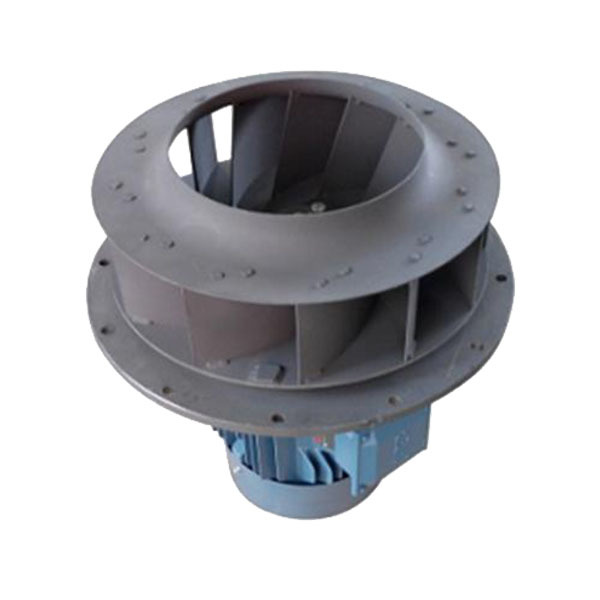

When the surrounding environment has strict requirements on the noise generated by the equipment used, the manufacturer needs to conduct vibration reduction and noise reduction treatment on the quality Centrifugal fan price, and carry out corresponding noise reduction and sound insulation treatment. What is the method of muffling? Let’s take a look at it briefly below!

Fans are mostly treated with sound insulation hoods. According to the type and size of the fan, various shapes of covers are made, which are spliced by multiple standard or non-standard sound insulation boards, and can also be made into an integral cover. The cover leaves the fan. Air intake and service door, other parts closed, exhaust pipe installed on top of cover to remove heat from motor running.

The sound-absorbing material of the FRP sound insulation cover adopts a non-metallic multi-layer composite structure, and the soft and hard sound-absorbing and sound-insulating materials are alternately arranged. The sound wave can act on different materials to produce reflection and absorption to achieve the effect of sound insulation and sound absorption.

The structure of the steel sound insulation board mainly adopts the method of internal suction and external partition. Its working principle is that when the vibration wave and airflow generated by the fan run at a high speed, the glass fiber cloth is gradually absorbed by the micropores of the ultra-fine glass wool board. Protection closed.

The unit is enclosed in a quality Centrifugal fan price room, so that the noise cannot be transmitted. The air inlet muffler should be installed in the sealed quality Centrifugal fan price room to meet the heat dissipation needs of the quality Centrifugal fan price air suction, motor, casing, etc.