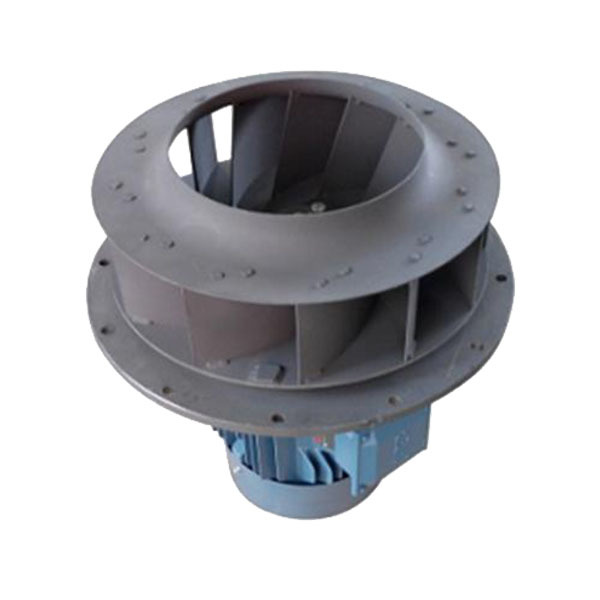

quality Centrifugal fan price breakdown maintenance knowledge

2022-05-06

The wear of the transmission parts is a common equipment problem, including the bearing position of the quality Centrifugal fan price, the wear of the bearing chamber, and the wear of the bearing position of the blower shaft. In view of the above-mentioned faults of quality Centrifugal fan price, traditional repair methods include surfacing, thermal spraying, electric brushing, etc., but they all have certain drawbacks: the thermal stress caused by the high temperature of repair welding cannot be completely eliminated, which is easy to cause material damage, resulting in bending or bending of parts. Fracture; and brush plating is limited by the thickness of the coating, which is easy to peel off, and the above two methods use metal to repair the metal, which cannot change the "hard-to-hard" cooperation relationship. Under the combined effect of various forces, it will still cause encapsulation Roller wear again.

Contemporary western countries mostly use the repair method of polymer composite materials to solve the above problems, and the most widely used is the American Fushilan technology system, which has comprehensive properties such as super adhesion and excellent compressive strength, and can be disassembled and machine-free. processing. There is no thermal stress of repair welding, and the repair thickness is not limited. At the same time, the metal material of the product does not have the concession, which can absorb the shock and vibration of the equipment and avoid the possibility of re-wear. The application also gradually replaces the traditional method.