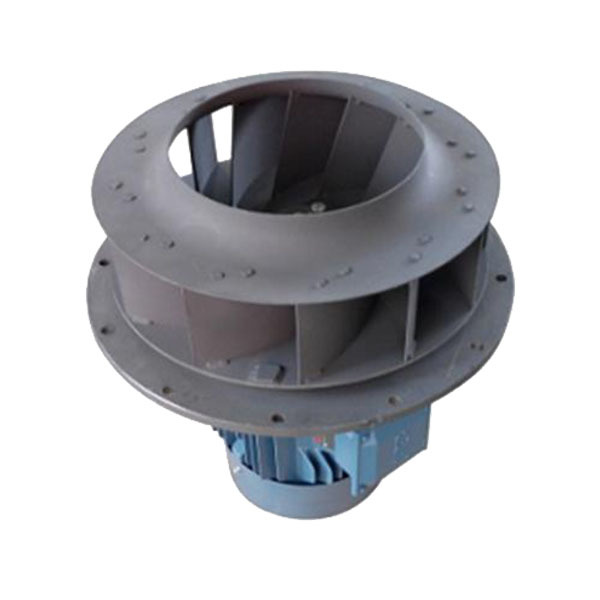

Installation of Centrifugal fan from China manufacturer

2022-04-21

1. The installation of the whole unit of Centrifugal fan from China manufacturer should be placed directly on the foundation and leveled with pairs of inclined horns.

2. For Centrifugal fan from China manufacturer assembled on site, the cutting surface on the base should be properly protected, and there should be no rust or manipulation. When the base is placed on the foundation, it should be leveled with a pair of inclined horns.

3. The bearing seat and the base should be closely connected, and the longitudinal non-levelness should not exceed 0.2/1000. Use a spirit level to measure on the main shaft, and the horizontal non-level base should not exceed 0.3/1000. Measurement.

4. Before grinding and scraping the bearing bush, the rotor axis line and the casing axis line should be corrected, and the gap between the impeller and the air inlet and the gap between the main shaft and the shaft hole of the rear side plate of the casing should be adjusted to make it conform to the equipment technology. document requirements.

5. When the main shaft and bearing bush are assembled, they should be checked according to the provisions of the equipment technical documents. An interference of 0.03-0.04 mm should be maintained between the bearing cover and the bearing pad (measure the outer diameter of the bearing pad and the inner diameter of the bearing seat).

6. Centrifugal fan from China manufacturer for rolling bearing assembly, the different axial degrees of the bearing holes on the two bearing frames can be flexibly rotated after the rotor is installed.

The above is a brief introduction to the relevant knowledge about the installation of Centrifugal fan from China manufacturer.